A Climate With Feedback and Self-Correction

March 01, 2019

What educators can learn from private-sector models about defining problems and evolving solutions

To successfully contribute to our democratic society, our children must know how to continuously self-improve. And given the responsibilities entrusted to educators by society to prepare students to be contributing citizens, we must continuously improve our own work as well.

We’re responsible for ensuring that our students learn to succeed. Whether the tests they’ll face are small or momentous, routine or episodic, individual or collective, their success will depend on knowing what to do and how to do it, backed by skills to act on that know-how.

Certainly, students must master established facts and concepts. Being prepared also means creating and mastering new capabilities by recognizing what isn’t working, determining why, developing and testing new approaches, and solidifying what works well.

Creativity Potential

Superb problem-solving abilities are hardly new necessities. Progression from hunting/gathering through herding and farming to industrialization and “post industrialization” depended on converting poorly understood, difficult situations into well understood, manageable ones. Even wrongly described and disparaged “low skill,” labor-intensive mass production of the 1940s, ’50s and ’60s required considerable problem-solving skill. Complex equipment was used for difficult tasks. Absent workers’ brains, brawn would have been for naught.

The problem-solving dynamic is easy to say (if sometimes hard to do), be it in laboratories, clinics, factories or studios. First is calling attention to things not working, then allowing time to find out why. This informs attempts at new approaches, which get codified as improvements and innovations.

In the 1970s and ’80s, many companies didn’t prioritize this learning dynamic as necessary for competitiveness. Instead, they treated people as cogs, at best dutifully following instructions. This ignored the creative potential of people to discover better approaches for better purposes.

For instance, assuming machines would replicate prescribed methods, one company created a factory with so few people that it could run “lights out.” However, robots couldn’t adapt to idiosyncrasies and eventually welded themselves immobile. General Motors nurtured adversarial labor relationships, lurching from crisis to crisis. (It is probably no surprise that societies repressive of free speech, press and dissent are least capable in providing for their people. Similarly, companies that don’t allow the professional safety to call out problems nor commit time to their resolution are ineffective and inefficient.)

Traditional Approach:

Continuous Learning Approach:

Calling Out Problems

In contrast, outrageous success accrued from enthusiastic seeing and solving problems. At Toyota, inspiration for many continuous-improvement programs that invested in problem-solving capability came from the shop floor through the senior ranks.

When lineside workers had trouble with a task, they pulled “Andon cords.” This was like industrial free speech, letting associates sound out that something was wrong. It was necessary to develop team leaders who reacted to the cord pull, but not with a “What did you do wrong?” scolding. Instead, they asked, “What’s the problem, and how can I help?”

Help wasn’t just workarounds. Calling out problems and swarming them informed diagnosis and treatment, skills for which training was provided. In turn, when team leaders had trouble, group leaders responded with inquiry and coaching, starting with, “What’s the problem, and what can I do to help?”

(For examples, see the Preface and Chapters 7 and 9 of my book The High Velocity Edge, downloadable at http://bit.ly/HVE_chapter_7, and http://bit.ly/HVE_Preface_1_9.)

In this way, Toyota transformed a terrible GM plant into one garnished with awards. The workforce was the same. The change was replacing repressive methods — those that led to dissent as grievances and other labor problems — with management that encouraged calling out and energetically responding to difficulty. Because this learning dynamic existed in early-stage design through production and delivery, Toyota’s profit per sale has been nearly three times Ford’s and four times that of other car manufacturing rivals.

In Classrooms

How does this translate to K-12 education? If being valuable depends on defining problems, running experiments and evolving better solutions, then students of all ages and levels — not just those older and “gifted” — should be coached to be creative, participating in writing, art, music, theater, science and engineering so they learn how to experiment to discover best answers.

Of course, students have to master fundamentals. Music without melody and harmony is noise. Art without composition and technique is a mess. Citizenship without history may well be anarchy. But even mastering established material can be continuously improved.

For example, if homework were assigned, collected, reviewed (not necessarily graded) and returned, then students could evaluate wrong answers to consider different solution approaches, and teachers could consider different instructional methods. That approach sets up more students for success on quizzes which, if used for diagnostic, continuous improvement, means more students achieve mastery on milestone tests.

In contrast, if homework is given and checked only for submission (and maybe graded but without review), then students won’t self-reflect on how to approach the material better and faculty won’t reconsider how they explained the material initially.

Students who struggled on homework will suffer with quizzes and will probably tank on exams. Teachers will say (as one did to my wife and me), “The class performed poorly on the test; I don’t know why.” Not having used the lesson plan dynamically — planned actions with predicted outcomes, refuted by how students actually did — the teacher couldn’t identify and rectify shortcomings — his and theirs.

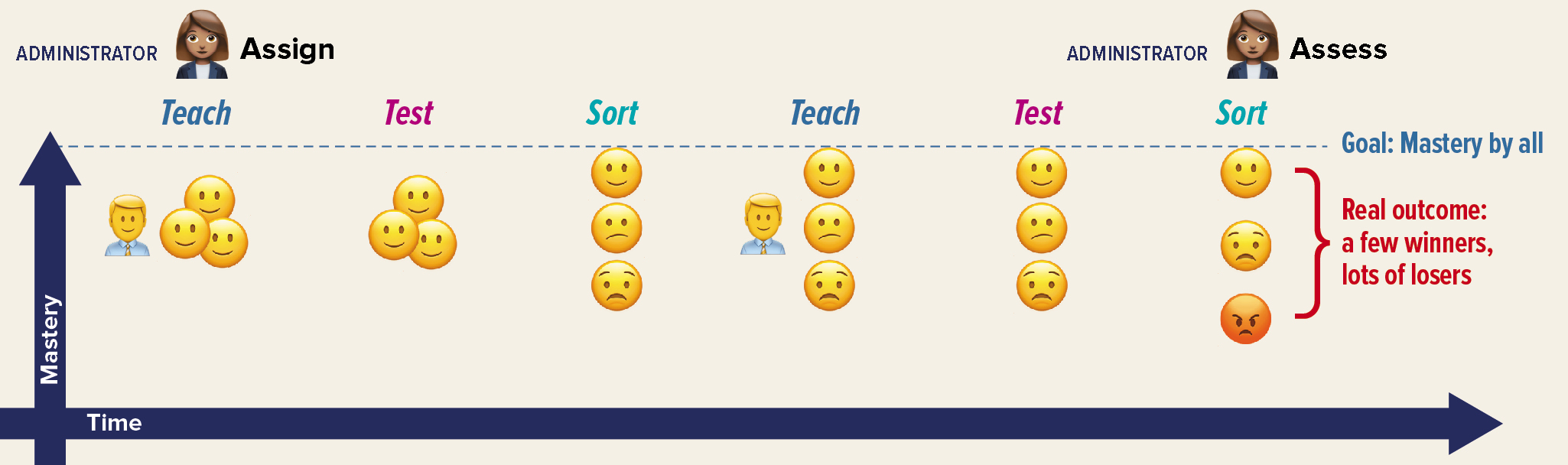

A Sorting Phenomenon

In the traditional model, we teach, evaluate, then sort students based on what they absorbed, given how we delivered the material and how they received it. Not surprisingly, those who “sorted” lower on early cycles screened farther and farther below the norm because neither we nor they have changed their approach.

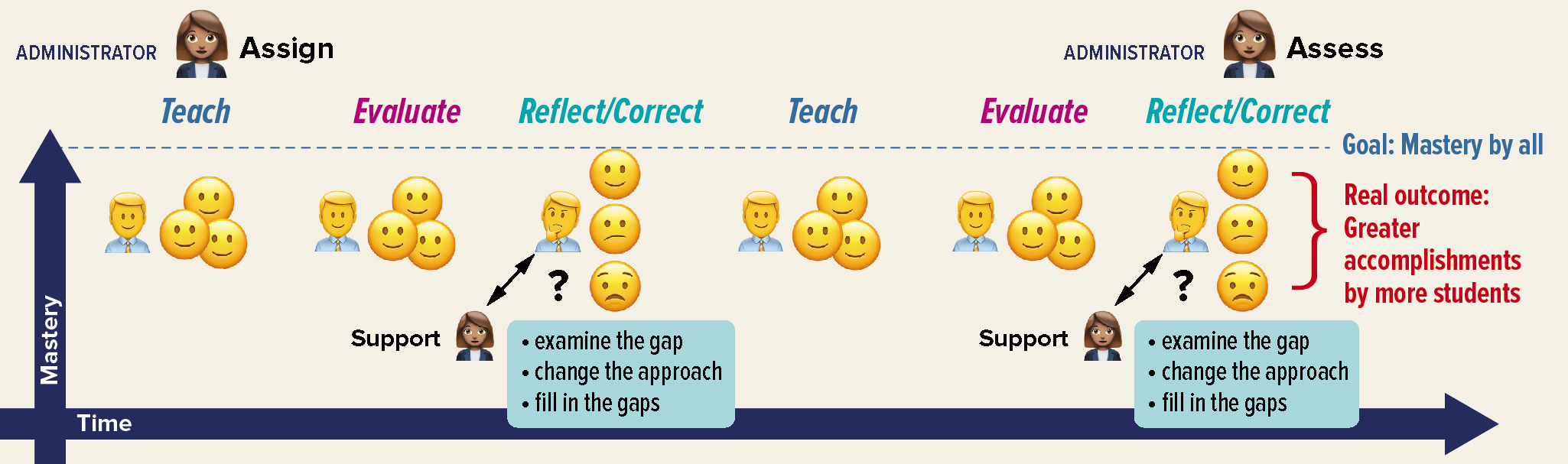

With a continuous-improvement approach, each cycle of deliver/receive is subject to reflection and correction, so we get better in tailoring our delivery by topic and student and they get better at receiving and mastering it.

In other words, continuous improvement means in part changing from broadcasting material at students who then are sorted into A, B, C and F buckets. It means planning, delivering, checking and adjusting to make qualitative and quantitative improvements in what is learned.

This conveys an important societal lesson. Students realize that to acquire mastery — in math, chemistry or philosophy — “wrong” is not bad if it inspires better. They’ll practice this themselves and see the same values modeled by their teachers. This equips all of them to keep getting better. That seems preferable to feeding expectations that life has few winners and many losers.

Rounding on Education

There’s a distinct role for school administrators in creating a dynamic where (ideally) everything provides feedback and informs self-correction.

A hospital’s chief medical officer provides an example of what that might look like in practice. This senior doctor at a large, prestigious academic medical center was challenged by wrong-side surgery, mis-medications and the like. A typical response would have been reviews and punishment. Instead, this chief medical officer took a continuous-improvement approach.

Each day he “rounded” on oncology, obstetrics, radiology and so forth, asking senior directors which patients had been treated the previous day and what specific difficulties staff experienced when providing care. Those most senior didn’t necessarily know details, but because the CMO kept returning, they started asking chief residents the same question. This caused the questioning to cascade to staff providing direct care at the bedside. In effect, the CMO was recreating the “supply chain” for help and support embodied in Toyota’s team leads, group leads and more senior leadership.

The chief medical officer added questions — not only “whom did you treat?” and “what was difficult?” (as opposed to “what went wrong?”) but also “what caused challenges?” “what corrective actions are you trying?” and “what’s working so far?” Finally, he added “From whom did you learn and to whom did you teach what you discovered?” Having staff learn to treat the system with the same discipline they used for treating patients led to decreases in complications and increases in care quality and staff satisfaction.

One can imagine school administrators having just such conversations: superintendents with their principals, principals with their deans and deans with their teachers. Doing so, they would break with the traditional model, in which we assign responsibility to faculty for students and topics and monitor to ensure adherence to the plan before evaluating at the end — mostly about what has been done and less so about what has been achieved.

In the continuous-improvement coaching model, like that of the group leaders at Toyota or the hospital CMO, we would be helping our colleagues recognize struggle points, supporting them in understanding the causes of those difficulties and helping them

develop and try changes in approach. Doing so gives schools a continuous-improvement learning dynamic that benefits all stakeholders.

About the Author

Steve Spear is a senior lecturer at the Massachusetts Institute of Technology Sloan School of Management in Cambridge, Mass., and author of The High Velocity Edge: How Market Leaders Leverage Operational Excellence to Beat the Competition.

Advertisement

Advertisement

Advertisement

Advertisement